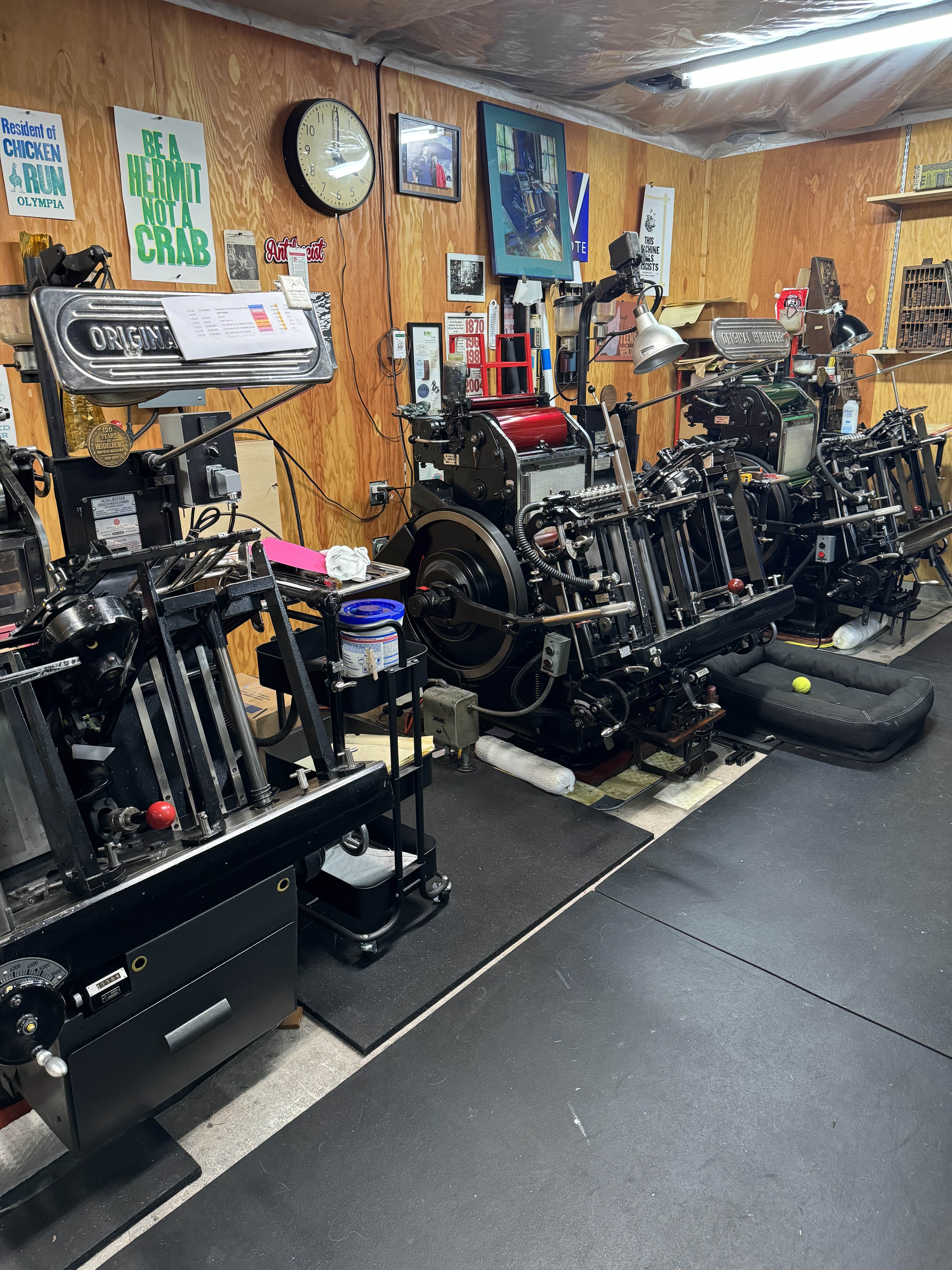

Since 1940, serving small businesses in Western Washington with design and letterpress printing.

Design to Print Letterpress

We offer our customers a complete solution from design to print to offer you the most efficient service. We are also very happy to work with your designs and designers to achieve the results you want.

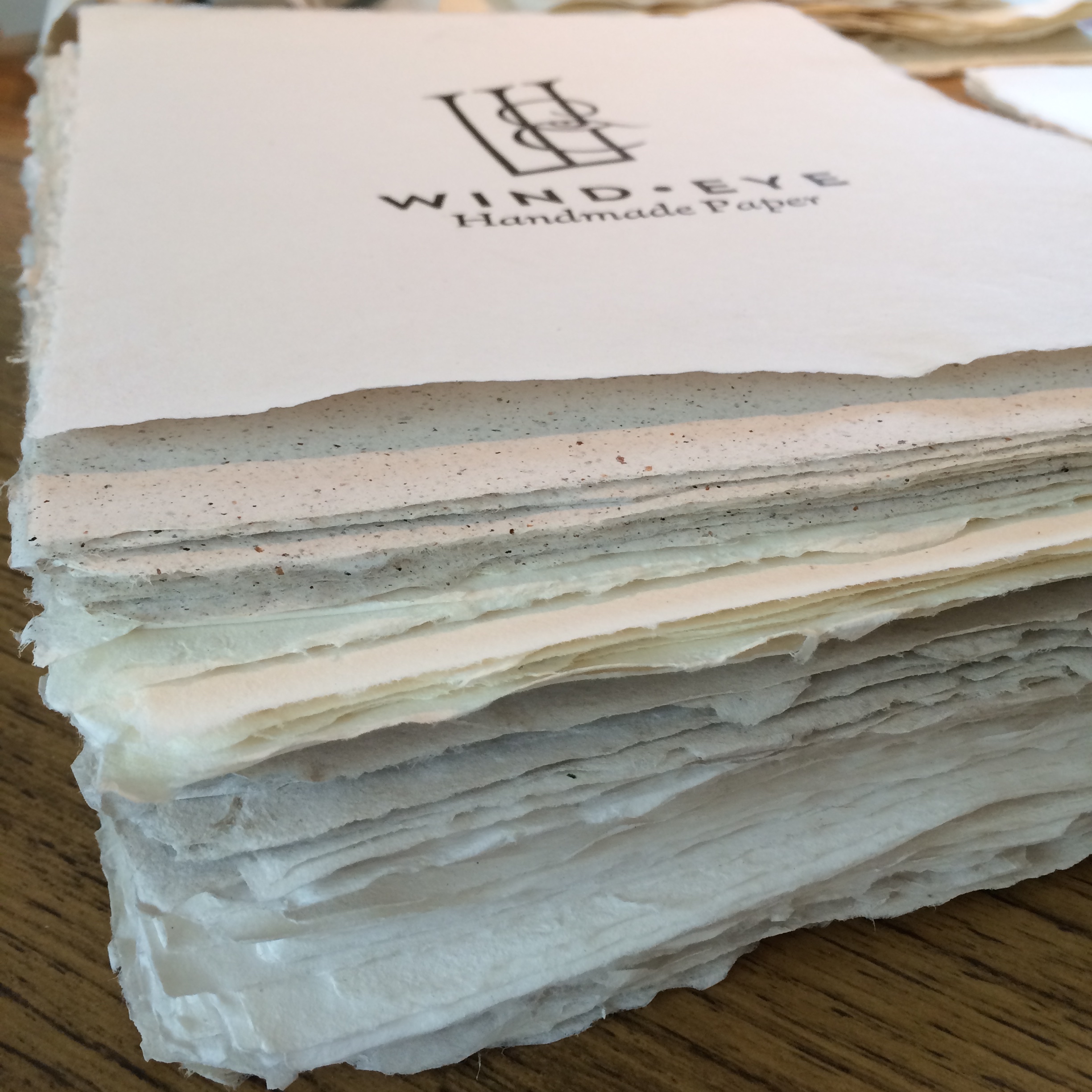

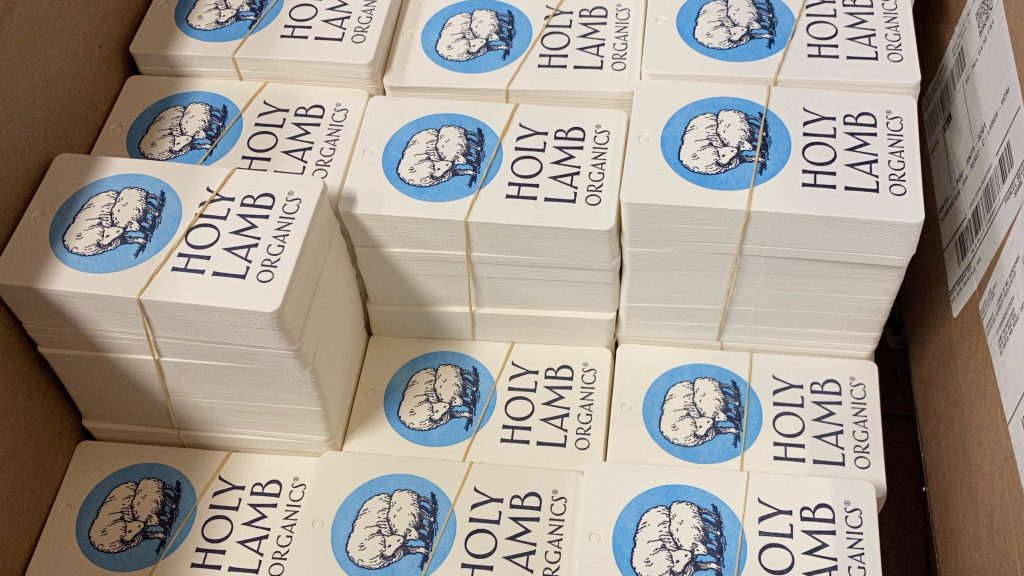

Custom Letterpress Labels & Tags

We offer custom label stocks not found anywhere else, and can die cut and print your custom labels and tags on our fleet of presses for unique, luxury results with impact.

Laser and Rotary Engraving

Talk to us about laser-engraving items for your business, and if you have special engraving needs, our rotary CNC machine might just do the trick!

Some of our esteemed customers who use our labels and tags on their amazing products —

“I highly recommend The Sherwood Press for all your printing and packaging needs. As a trusted and reliable printing service, The Sherwood Press consistently delivers top-notch quality and attention to detail. For unparalleled quality, reliability and customer satisfaction, choose The Sherwood Press.”

Oliver Stormshak, Owner, Olympia Coffee Roasting Co.

Get In Touch

I look forward to hearing from you!

hello@thesherwoodpress.com

(360) 357-3855

811 5th Avenue SW

Olympia, Washington 98502

Opening Hours

Mon-Fri

9 am — 5 pm

Sat, Sun

Closed

Designed with WordPress